Infrared Camouflage

Smart Material Solutions (SMS) has developed an infrared (IR) camouflage film with spatially varying emissivity that conceals objects in the infrared by softening thermal edges and introducing naturally occurring, customizable patterns to reduce detectability and trackability.

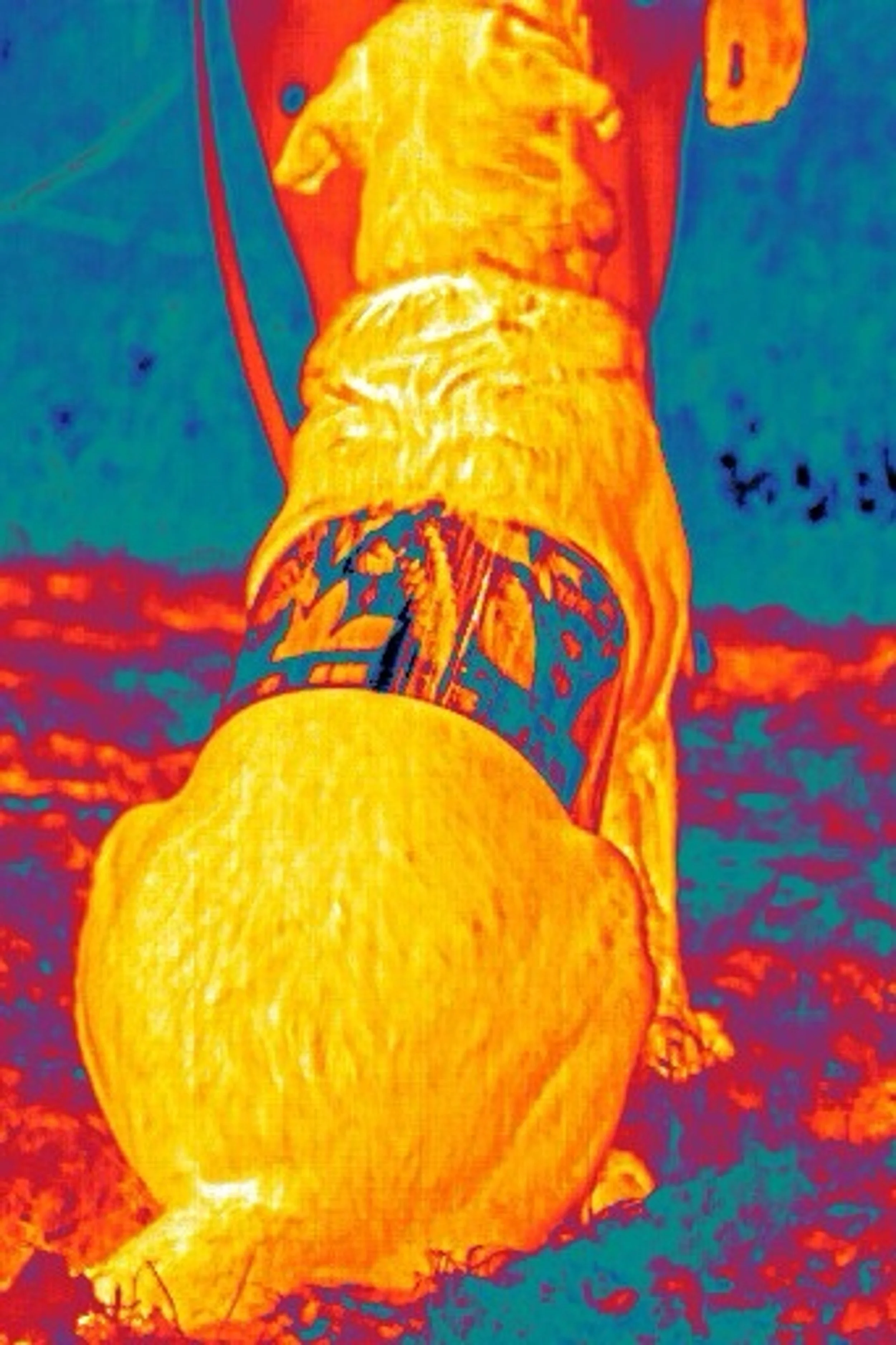

Dog with IR Camo belt

The technology leverages the advanced optical properties of metamaterials, which were previously limited to lab-scale demonstrations. Using SMS’s nanomanufacturing platform, these structures can now be produced at scale in flexible film form factors. Initial prototype testing demonstrates the film’s effectiveness as infrared camouflage across a range of thermal conditions.

SMS is actively seeking partners and funding to support field testing, further performance improvements, and manufacturing scale up.

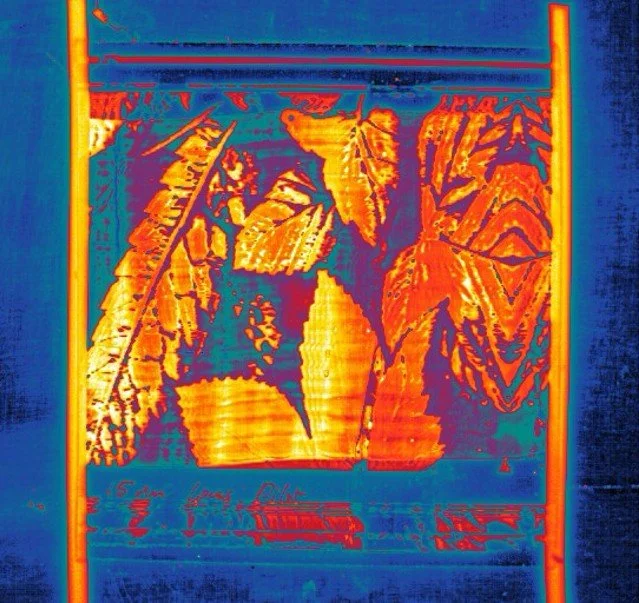

Prototype Film & Demonstrations

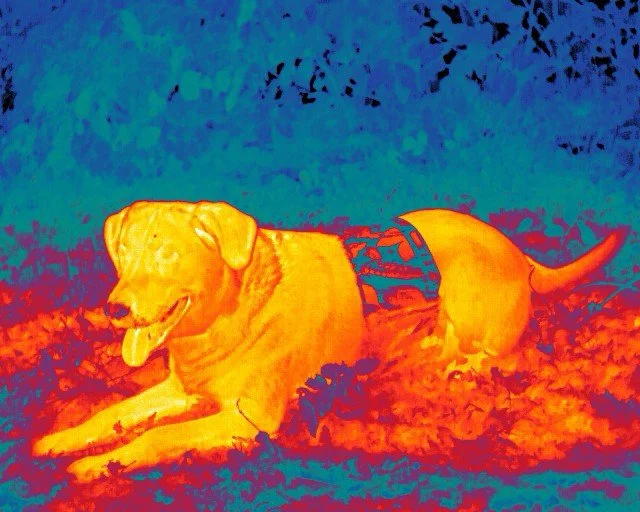

IR Camo Film Belt on a Dog

Lyra, our Chief Security Officer, helped us demonstrate how the IR Camo Film can hide a living being by wearing a belt made of our prototype IR Camo Film and posing for pictures outside. The belt, patterned with a foliage pattern, helped her midsection blend in with the surroundings.

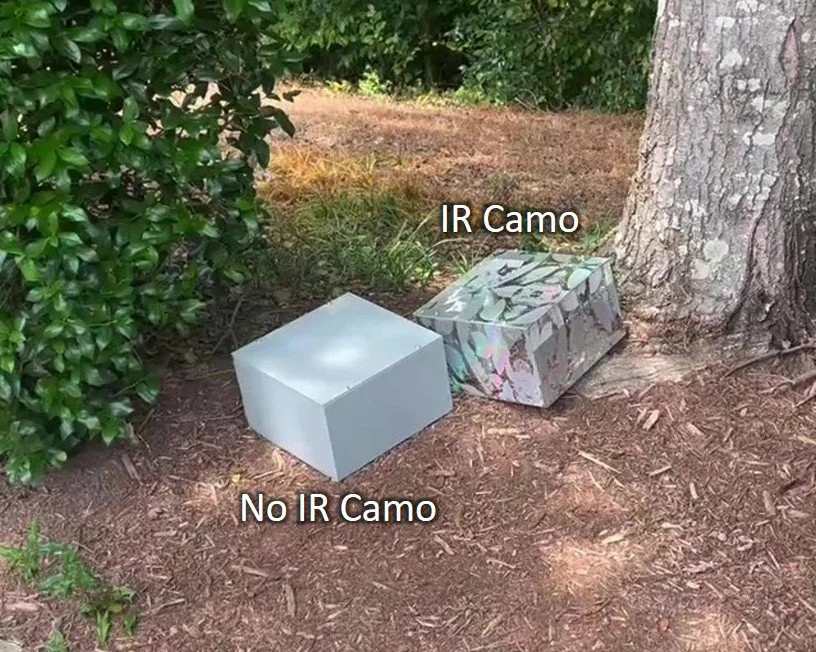

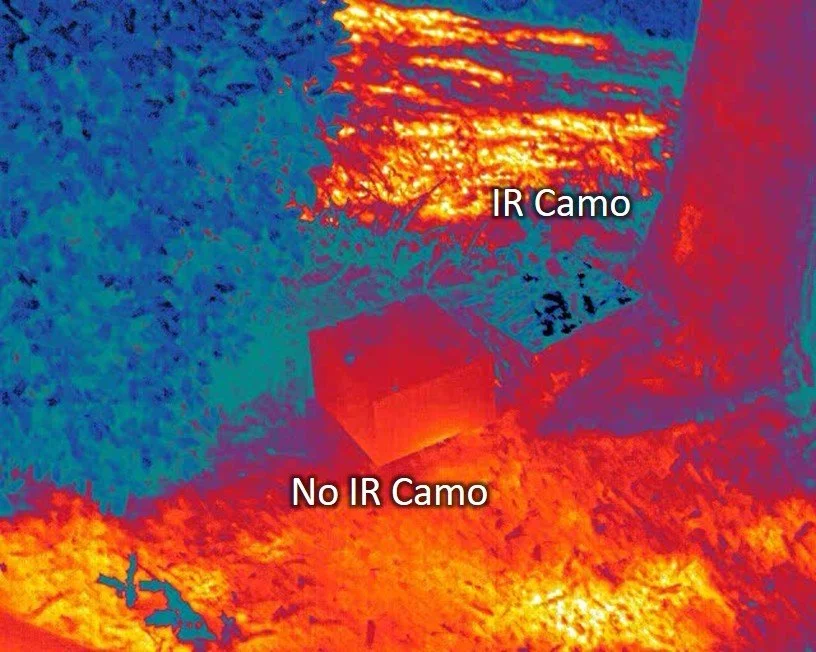

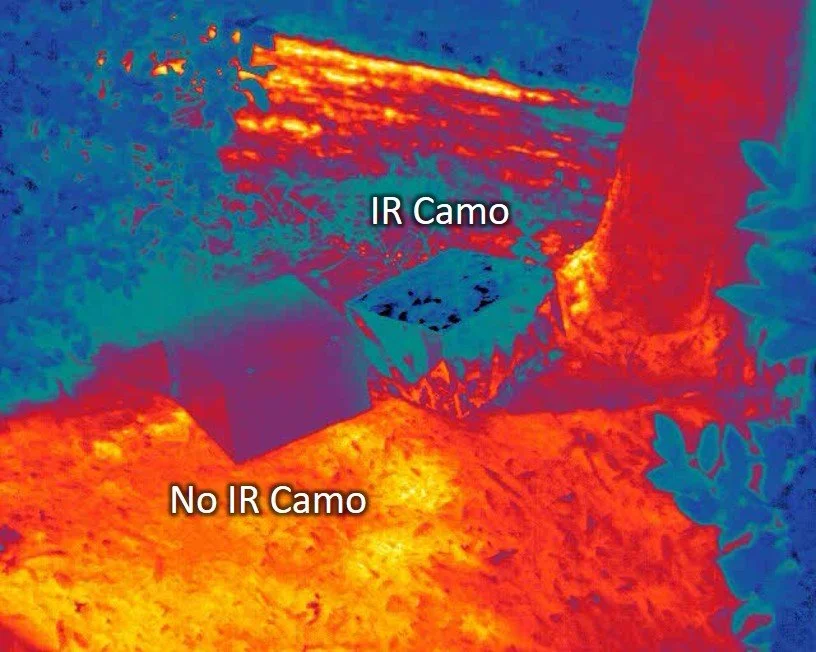

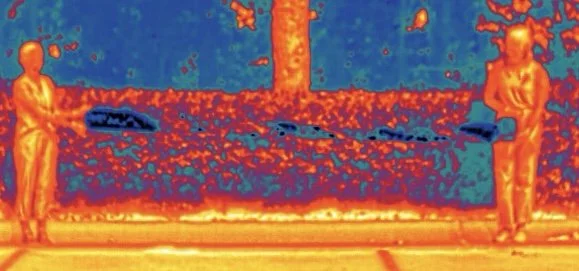

IR Camo Film on Boxes

The prototype IR Camo Film was also applied to the exterior of a box to demonstrate its ability to obscure sharp geometric edges. A box covered with the IR Camo Film was directly compared to an identical box painted gray with no camouflage treatment. The IR Camo Film significantly reduced the edge contrast in infrared imagery, both when the box was at ambient temperature and when it was internally heated, demonstrating performance across realistic thermal scenarios.

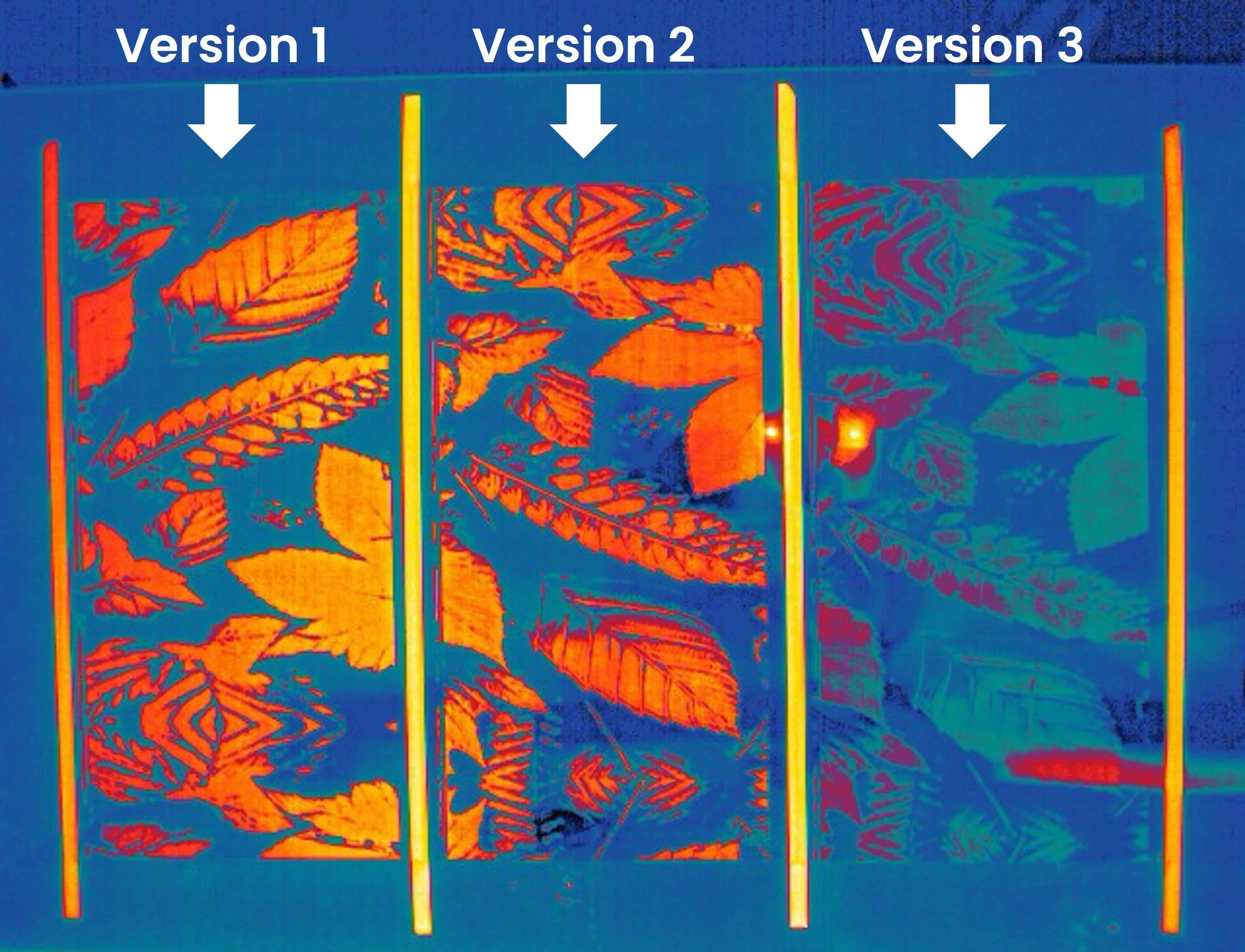

Customizable Patterns, Emissivity Contrast, and Visible Appearance

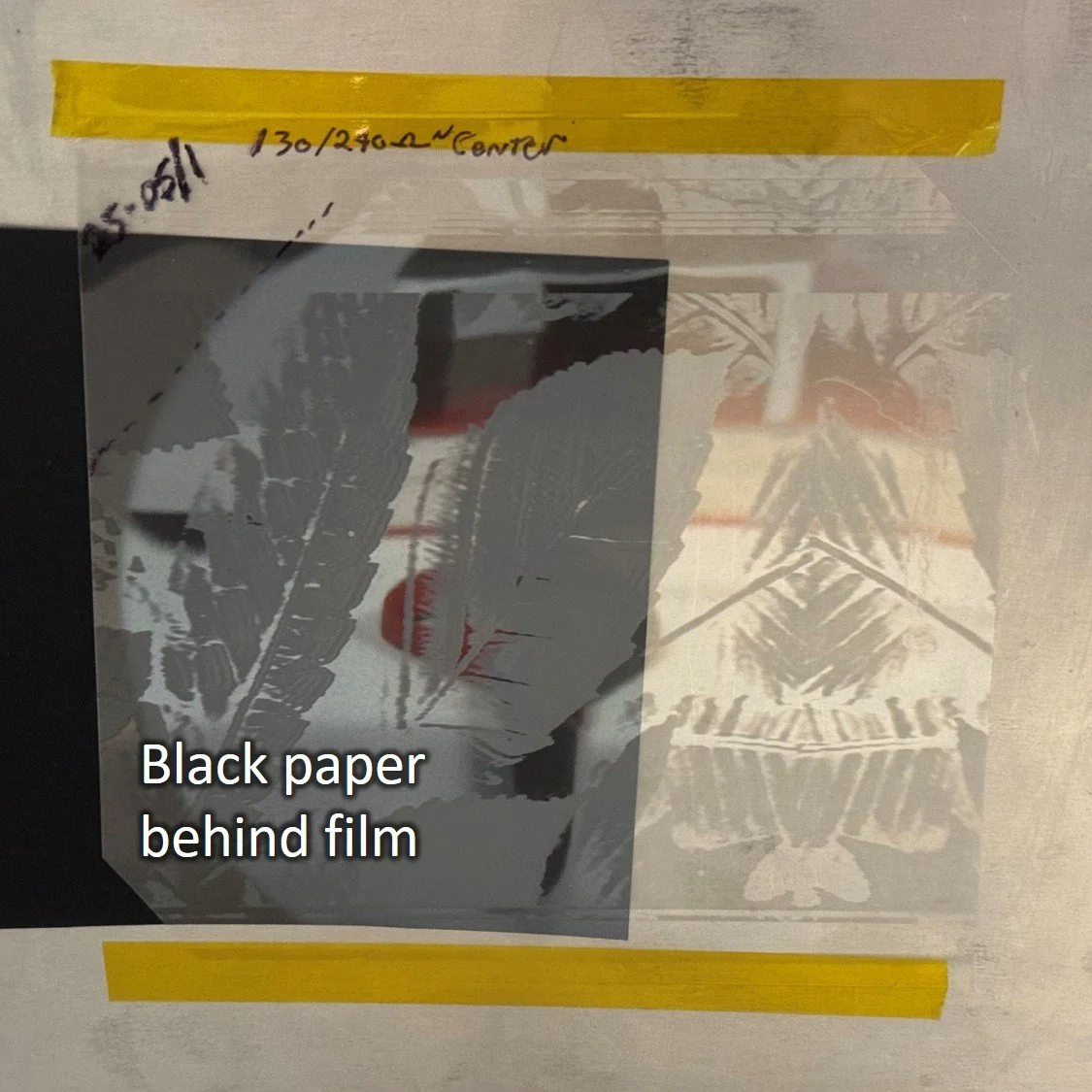

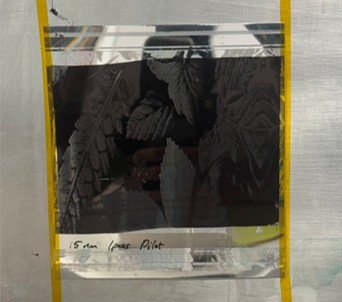

The IR Camo Film offers customizable patterns and emissivity contrast. Although the prototype film is reflective in the visible region, SMS has already demonstrated the ability to make a visibly transparent and opaque IR Camo Films in the lab. Future work will focus on improving transparency and opacity while maximizing IR contrast.

Scalable Manufacturing

The IR Camo Film was produced using SMS’s scalable metamaterial manufacturing processes. During an SBIR effort, SMS created several hundred feet of a prototype IR Camo Film using nanocoining and roll-to-roll nanoimprint lithography (R2R NIL). With equipment upgrades, this process is scalable to widths exceeding one meter and lengths of tens of thousands of feet, enabling commercial-scale production.

Next Steps

SMS is seeking partners, end users, customers, and other interested stakeholders to help advance the IR Camo Film toward real-world deployment. We are particularly interested in engaging with groups that can provide operational feedback, use-case insights, introductions to relevant programs or customers, or funding for continued development.

Planned development efforts include:

Field testing in representative operational environments

Performance improvements informed by end-user feedback

Fabrication of large-area visibly transparent or low-reflectance IR Camo Film

Development of a version that can be applied similarly to automotive wrap vinyl

Scaling up manufacturing

If you are an end user, potential customer, investor, or stakeholder interested in evaluating the technology, providing feedback, or supporting further development, we would welcome a conversation. Please contact us to learn more or request a free sample!